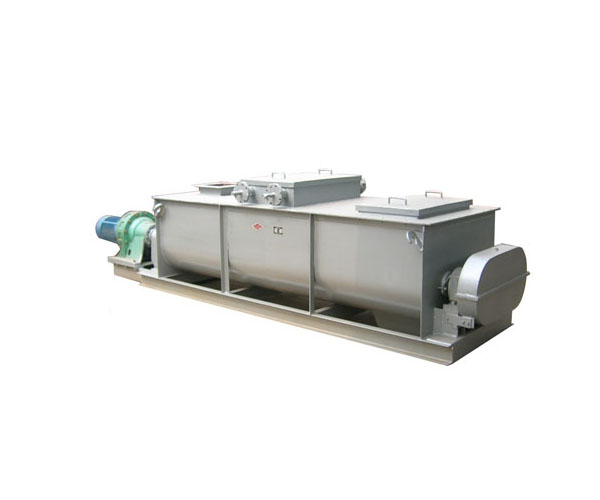

該螺(luo)旋喂(wei)料機(ji)适用(yong)于幹(gan)燥粉(fen)狀物(wu)料(如(ru)煤粉(fen)、水泥(ni)、谷物(wu)、砂石(shi)等)的(de)均勻(yun)連續(xu)供料(liao)。

The device is used to continually supply dry power material, such as coal power, cement, grain and sand etc.

The device is equipped with cycloid pin wheel speed reducer and VF transducer. It has the features of great range of timing, smooth operation, low noise, compact structure and small volume. It can adjust flow of material expediently and meet the demand of different production technics.

Model explanation:

進(jin)出料(liao)口中(zhong)心距(ju) mm Center interval of inlet and outlet

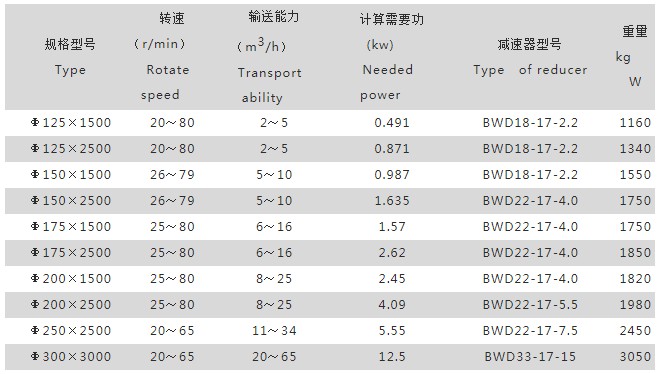

雙管(guan)螺旋(xuan)喂料(liao)機主(zhu)要技(ji)術參(can)數:

Main technical parameter:

喂(wei)料能(neng)力計(ji)算:

式(shi)中:

Q---雙(shuang)管螺(luo)旋喂(wei)料機(ji)的喂(wei)料能(neng)力(m3/h)

Feeding ability

Diameter of screw leaf

d---螺旋(xuan)杆直(zhi)徑(m)

Diameter of screw pole

S---螺(luo)旋的(de)螺距(ju)(m)

Interval of screw

δ---螺旋(xuan)葉厚(hou)度(m)

Thickness of screw leaf

n---螺(luo)旋的(de)轉速(su)(r/min)

Rotate speed of screw

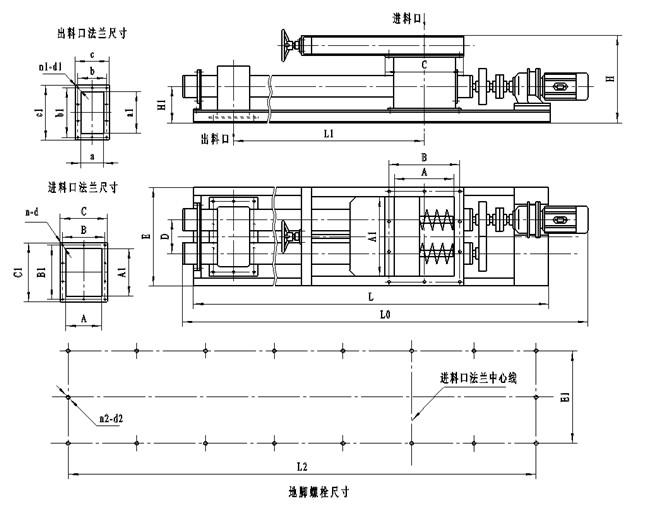

SLW外(wai)形圖(tu):

SLW外形(xing)連接(jie)尺寸(cun):

Appearance joint dimension:

c×c1 | n1-d1 | B×B1 | |||||

Φ125×1500 | 200×500 | 20-Ф13 | 620×620 | ||||

Φ125×2500 | 200× | 320×620 | 20-Ф13 | 500×500 | 570×570 | 620620 | |

Φ150×1500 | ×600 | ×670 | 320×720 | 24-Ф13 | 670 | 720×720 | |

Φ150× | 200×600 | 270×670 | 320×720 | Ф13 | 670×670 | 720× | |

230×700 | ×780 | 28-Ф13 | 700×700 | 780× | ×830 | ||

Φ175×2500 | 230× | 310780 | ×830 | 700700 | |||

Φ200×1500 | 390×940 | 28-Ф13 | 880×880 | 940×940 | |||

Φ200× | 28-Ф | ×800 | 880×880 | 940×940 | |||

Φ×2500 | 250×1000 | 330×1080 | 390×1140 | 36-Ф13 | 1140×1140 | ||

Φ300×3000 | 250× | 330×1280 | 44-Ф | ×1200 |

SLW外形(xing)連接(jie)尺寸(cun):

H | H1 | L0 | L1 | D | E | E1 | |||||

Φ× | 16-18 | 268 | 620 | 570 | |||||||

16-Ф18 | 32-22 | 268 | 4000 | 250 | 620 | 3950 | 570 | ||||

150×1500 | Ф | 26-Ф | 650 | 275 | 1500 | 300 | 720 | 2950 | 670 | ||

Φ150× | 16-Ф18 | 34-Ф22 | 650 | 275 | 4000 | 2500 | 720 | 3950 | 670 | ||

Φ1751500 | 20-Ф18 | Ф | 275 | 4150 | 1500 | 830 | 3150 | 780 | |||

20-Ф18 | 36-22 | 678 | 275 | 4200 | 5150 | 2500 | 350 | 830 | 4150 | ||

Ф22 | 683 | 305 | 3430 | 4380 | 400 | 940 | 3370 | ||||

Φ×2500 | 20-Ф18 | 36-Ф22 | 683 | 305 | 4430 | 2500 | 400 | 940 | |||

Φ250×2500 | 24-Ф23 | 42-Ф22 | 728 | 4850 | 5800 | 2500 | 570 | 1140 | 4790 | 1080 | |

Φ300×3000 | 32-Ф | 796 | 385 | 5550 | 6500 | 3000 | 1340 | 5490 | 1280 |

Usage explanation:

l 機(ji)體裝(zhuang)妥後(hou)應檢(jian)查各(ge)存油(you)處是(shi)否有(you)足夠(gou)潤滑(hua)油。

l 運(yun)行應(ying)平穩(wen)可靠(kao),軸承(cheng)箱不(bu)得發(fa)生漏(lou)油現(xian)象,軸(zhou)承溫(wen)升不(bu)得超(chao)過20℃。

l 必需(xu)保證(zheng)輸送(song)機無(wu)負荷(he)起動(dong),在停(ting)車前(qian)應停(ting)止加(jia)料,待(dai)機殼(ke)内輸(shu)送完(wan)物料(liao)後,方(fang)能停(ting)止運(yun)轉。

l 使(shi)用中(zhong)應經(jing)常檢(jian)查各(ge)機件(jian)的工(gong)作狀(zhuang)态,注(zhu)意各(ge)傳☎️動(dong)件是(shi)否運(yun)行良(liang)好,應(ying)經常(chang)加潤(run)滑油(you)。

l The error of portrait linearity and horizontal of body and bracket is the 1/1000 of length when install screw engine. Install the support on the body steadily and then lock down the ground bolt.

l Install the inlet and outlet on the spot. Add sealing shim between the two flanges and there is no clearance.

l Check the oil store if there is enough lubricant after the installation is over.

l The operation should be steady and reliable. There is no oil leakage in the bearing box and the raising temperature is not more than 20℃.

l Feed the material equally, otherwise the material will be jammed and the driving device is over loaded. There is no big block hard material in the transported material to avoid blocking and damaging.

l Make sure that the conveyer starts without load and stop feeding before stop the engine. Stop the conveyer after the material is transported completely.

- 上一(yi)條信(xin)息:空(kong)氣提(ti)升器(qi) KT-Ⅰ

- 下一(yi)條信(xin)息:粉(fen)塵加(jia)濕攪(jiao)拌機(ji)